Electroniquel | Grounding rods

PROTECTION

grounding rods

The basic function of an Earthing system is to limit the voltage to earth, which makes it possible to ensure the performance of the protections and eliminate or reduce the risk of a breakdown in the electrical materials used.

Electroníquel is a pioneer in Europe in the design and manufacture of protective and grounding elements. Our different production lines allow us to manufacture rods, electrodes, accessories, plates, meshes, terminals, connectors and derivations, elements that allow us to have comprehensive control in the event of overvoltages or natural electrical discharges.

great mechanical rigidity

maximum corrosion resistance

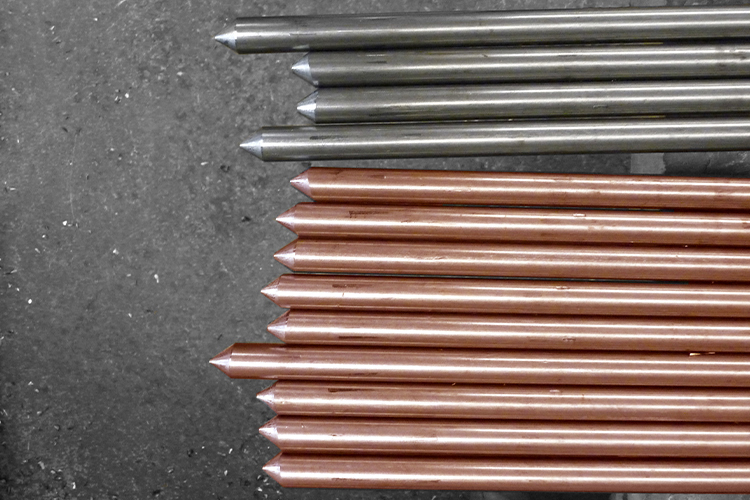

ELECTRONIQUEL stakes are easy to install cylindrical electrodes with a steel core and a thick layer of pure electrolytic copper molecularly bonded together. Due to this molecular bond, steel and copper are physically inseparable and therefore, when faced with corrosion attacks, they behave as electrodes of the highest quality and durability. Valid for any type of grounding: lightning rod, home, antennas, machinery, instrumentation ...

Ground Rods

Electroniquel is one of the main European manufacturers of Earthing since the 70s. Currently our pikes are buried in thirty countries in all types of facilities, electrical generation and distribution, residential, rail ...

+ infoEARTHING GROUNDING STAPLES

As a complement to its steel-copper rods, Electroniquel manufactures an extensive range of accessories in brass and bronze to cover all the needs in the earth network, staples for stakes and cable, for cable with cable, cable with metallic structures

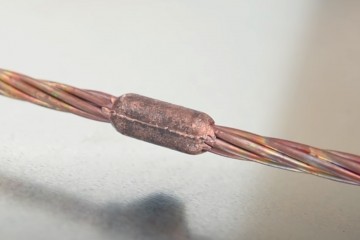

+ infoexothermic welding

Aluminothermic welding is a procedure in which, thanks to the reaction caused by the reduction of copper oxide by aluminum, a durable union of two metal elements (copper-copper or copper-steel) is obtained. The connection is resistant to overload and corrosion.

+ info Fabrication process

GROUNDED SPARES

Materials selection

Covering

marked

Inspection

CEEIS CEEIS TEST View Report

Results obtained in tests carried out on ELECTRONIQUEL grounding electrodes

ELECTRICAL TEST VIEW REPORT

Results obtained in tests carried out on ELECTRONIQUEL grounding electrodes

Characteristics

Protection of people and equipment

It limits the stress of the metal parts in an installation with respect to the ground and therefore allows other protection devices such as circuit breakers to function properly.

Great durability and savings

The installed elements have sufficient protection against corrosion, as well as galvanic compatibility in all installed parts.

AFME Member

With product quality certificate in AENOR, and manufacturing under the most demanding international standards and customer specification.

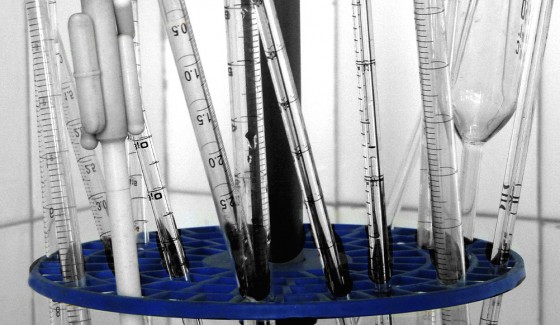

own laboratory

Laboratory to carry out corrosion tests on the materials to be installed.

electrolytic copper plating

We manufacture earth rods with calibrated steels with low carbon content to guarantee its hardness in the installation.

Developement

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium.

Electrical resistivity

1.

Sandy grounds From 1,500-10,000 Ω / m

2.

Swampy soils Up to 5-100 Ω / m

3.

Optimal terrain 50-100 Ω/m

protección de personas y equipos

UNE 202006 (2019) APPLICATION STANDARD

“Grounding electrodes for low voltage installations. Cylindrical steel-copper attachable picks and their accessories "

UNE 21056 (1981) APPLICATION STANDARD

“Grounding electrodes. Cylindrical steel-copper attachable picks ”

UL 467 (2013) APPLICATION STANDARD

“Standard for safety. Grounding and bonding equipment”

EC 62561-2 (2018) APPLICATION STANDARD

"Lightning Protection System Components (LPSC) - Part 2: Requirements for Conductors and Ground Electrodes"