tinned

Highly electrically conductive

Tin-plating

lead-free process

tin-plating

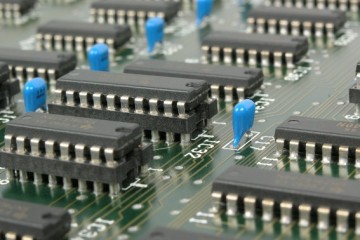

Tin plating is a metallic tin coating by electrolytic bath that can be applied on stainless steel, different types of steels, iron, aluminium, brass and different types of copper to increase protection against oxidation, corrosion, attack by weak acids, neutral salt solutions and wear, it is highly conductive, solderable and food compatible and gives a nice shiny aesthetic finish. This treatment is a good alternative to silver and is very common in the electrical and electronic equipment, consumer goods, food, decoration, fashion and automotive industries for its anti-corrosion and electrical conductivity properties.

tin-plating

tin-plating

The entire tin plating process is carried out by complete immersion of the pieces in a battery of tanks, each with different compositions and missions.

Treatment

Deposition

Inspection

Tin plating characteristics

Silver to white finish

Matt to very glossy shade, ideal for both technical and decorative purposes

Good weldability

Insulators with ceramic parts are not chemically attacked by the deposit or leaded glass.

Aldehyde-free process

High reflectivity and electrical conductivity

Non-toxic metal

Can be used for food contact parts

Good corrosion resistance

Protects against oxidation and wear, extending the useful life of the products.

High conductivity

Avoids high current losses and improves signal transmission.

Protección contra la corrosión 170 ºC

Dureza hasta 220 °C

Resistencia térmica hasta 900 °C

Tin plating application

certifications and standards

ELECTRONIQUEL CERTIFIES ALL ITS TREATMENTS BASED ON THE SPECIFIC STANDARD, APPROVAL OR TESTS

ISO 2093:1986 CERTIFICATION

Electroplated coatings of tin – Specification and test methods

(RoHS) 2002/95/CE Directiva

De la Industria electrotécnica y electrónica