Zinc Níquel

PROTECTION

Electrical Earthing

PROTECTION

Zinc alloy with nickel

PROTECTION

According to standards: DIN 50979 and ISO 15726 Clear or black passivation. Possibility of applying sealant in any of the cases. Alkaline process for the electrodeposition of a zinc-nickel alloy with a nickel content of 12-15%. Exceptional protection against corrosion with high temperature resistance is achieved by meeting the demands of the automotive industry, even after thermal shock. Compatible with light metals and is an ideal base for subsequent treatments free of hexavalent chromium that meet the European standard ELV

+ infoPROTECTION

GENERAL PROCESS Zinc Nickel

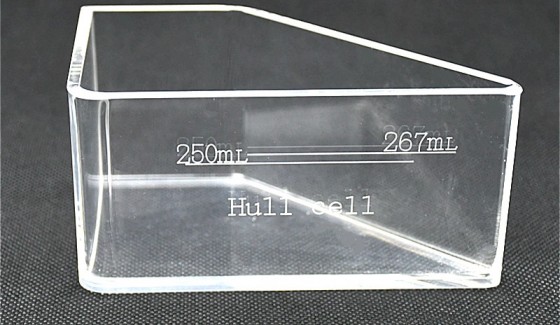

The entire Zinc Nickel process is carried out by completely immersing the parts in a battery of vats, each with different compositions and missions.

Treatment

Deposition

Dehydrogenated

Passivated

Inspection

coding of ELECTROLYTIC coatings

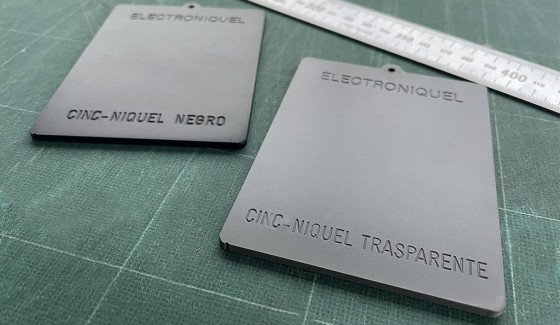

TRANSPARENT PASSIVE NICKEL ZINC

IRIDESCENT PASSIVE NICKEL ZINC

ZINC NICKEL PASSIVE BLACK FINISH

IRIDESCENT PASSIVE NICKEL ZINC sealing

PROTECTION

good thermal conductivity

Resistant to temperature even after the realization of a thermal shock

Transparent and black finishes

There is the possibility of applying subsequent seals to guarantee the requirements of white corrosion.

Homogeneous texture

The resulting alloy offers a good distribution of the metal obtaining matt or satin gray or black finishes.

Contains trivalent chromium

All Zinc Nickel finishes contain trivalent chromium and are cyanide free

Drum application

Static or rack application

Good base for other applications

Its good behavior stands out as a base for the application of paints, Kataphoresis and electrophoresis

Excellent substitute for Zinc Flake

It is applied to those pieces that due to their geometry cannot be treated with Zinc Lamellar as flat pieces, with holes, blind holes ...

PROTECTION

PROTECTION

480 h | 5 microns

750 h | 8 micras

1000 h | According to characteristics

certifications and standards

ELECTRONIQUEL CERTIFIES ALL ITS TREATMENTS BASED ON THE SPECIFIC STANDARD, APPROVAL OR TESTS

DIN 50979 standard

Metallic coatings - Electroplated zinc and zinc alloy coatings on iron or steel with supplementary Cr(VI)-free treatment

ISO 19598:2016 Certification

Metallic coatings. electrolytic coatings of zinc and zinc alloys on iron or steel with supplementary treatment without Cr (VI)

ASTM B841:1999 SPECIFICATION

Standard specification for electrodeposited coating of czinc nickel alloy deposits